Advantages at Receiving Point

QUALITY, QUALITY, QUALITY:

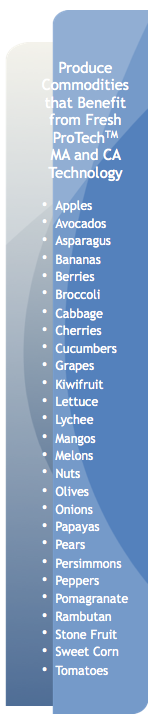

Fresh ProTech® Gas 'N Go® provides the highest quality systematic approach to post harvest treatment of product that is truly sealed at the source. Modified atmosphere is applied automatically into each wrapped pallet, based on sensors monitoring the atmosphere of each load, which results in a more precise application of atmosphere.

TAMPER EVIDENT:

The multi-layer application of the specially designed and manufactured stretch film material on each pallet provides a complete seal for tamper evident packaging and food protection. Upon arrival, portions can be cut away for inspection without requiring full removal of the material, if the cold chain is maintained.

STABLE FOR THE LONG HAUL:

Each sealed pallet with the modified atmosphere is fully enclosed with super stretch wrap, which provides complete stability for each pallet. The end result is a more stable ride and improved quality to the consumer. The wrap is extremely secure, and no corner boards are required on the load. The clear plastic also allows for full visibility of the packaging inside.

LONGER SHELF-LIFE, LESS SHRINK:

Our patented Fresh ProTech® Plus process is now commercially available for berries and other produce. Fresh ProTech® Plus includes a safe and effective sanitizer treatment that is injected along with CO2 that is scientifically proven to reduce decay and improve shelf-life more effectively than CO2 alone.

Gas 'N Go Systems

Deliver accurate commodity specific atmosphere and sanitizing treatments into MAP pallet enclosures

Vac 'N Pac Systems

Provide vacuum infusion treatments in conjunction with a modified atmosphere packaging process

Plug 'N Play Systems

Offer both modified and controlled atmosphere options for storing pallets in a low cost and flexible manner

Chamber Systems

Afford very reliable CA storage solutions using modular chambers inside of exiting facilities

FAQ

To get additional information fill out the contact us form or check out frequently asked questions